Table of Contents

Rotary encoder modules are essential components in modern electronics, offering precise detection of angular positions and rotation. These sensors are widely used in various industries, including robotics, automation, and consumer electronics, due to their reliability and versatility.

If you are building a project that requires position sensing, a rotary encoder is likely an essential component. Whether you’re working with an Arduino, Raspberry Pi, or other microcontrollers, integrating a rotary encoder module can make your project more efficient and responsive.

To get started, understanding the working principle and types of rotary encoders can provide insight into how they function in real-world applications. For example, check out this Arduino Rotary Encoder Tutorial to learn how to interface rotary encoders with your microcontroller.

In this article, we’ll explore the fundamental aspects of rotary encoder modules, their applications, benefits, and tips for integrating them into your projects.

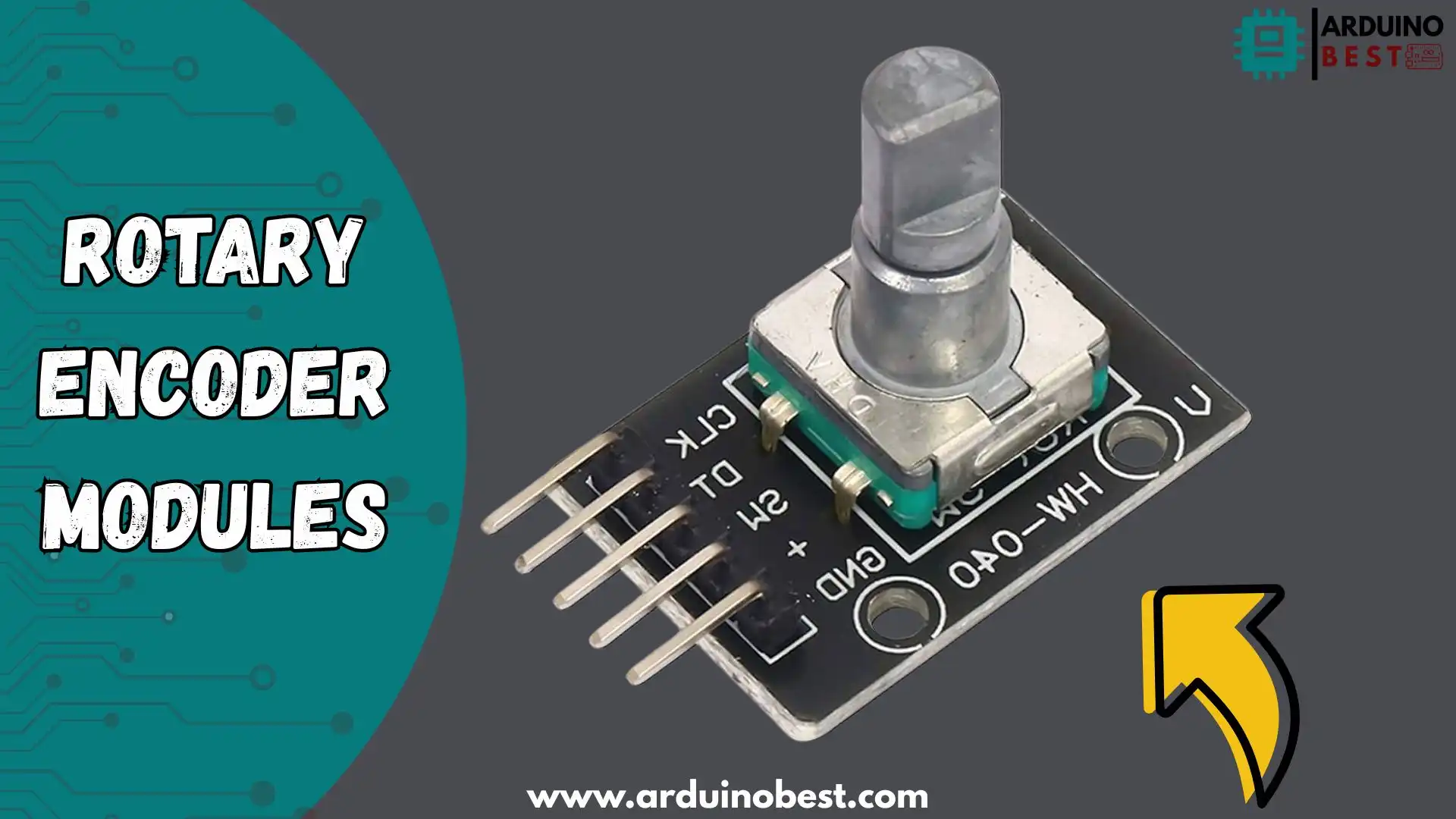

What is a Rotary Encoder Module?

A rotary encoder module is an electromechanical device that detects the angular position or rotation of a shaft or axle. This module translates rotational motion into an electrical signal that can be interpreted by electronics like microcontrollers or digital systems.

Key Types of Rotary Encoders

- Incremental Encoders: These encoders generate a series of pulses as the shaft rotates. Each pulse represents a fixed amount of movement, making them ideal for measuring relative position.

- Absolute Encoders: Unlike incremental encoders, absolute encoders provide a unique code for each position, making them capable of identifying the exact angle even if power is lost and restored.

For more on the different types, visit this Rotary Encoder Technology Overview.

How Do Rotary Encoders Work?

Rotary encoders work by translating the rotation of a shaft into an electrical signal. This is usually achieved through a disk or wheel with patterns that interact with a sensor, such as an optical or magnetic sensor. The sensor detects changes in the pattern as the disk rotates, sending out a signal that can be processed by a microcontroller.

Components of a Rotary Encoder

- Disk or Shaft: The part that rotates.

- Sensor: Detects the movement of the disk, typically optical or magnetic.

- Output Signal: The signal sent to the microcontroller, typically in the form of pulses.

Types of Rotary Encoder Modules

There are primarily two types of rotary encoder modules: incremental and absolute encoders. Each type serves different applications and has distinct advantages.

1. Incremental Encoder Modules

- Measures the change in position rather than the absolute position.

- Sends out pulses that the controller counts to determine position.

- Simple and cost-effective.

- Ideal for applications where you only need relative position changes.

2. Absolute Encoder Modules

- Provides the exact position of the shaft.

- Can identify the exact angle even after power loss.

- More expensive but essential for high-precision applications.

Applications of Rotary Encoder Modules

Rotary encoder modules are found in various applications where precise measurement of rotational movement is needed. Some of their key applications include:

- Robotics: Used to detect the position of a motor’s shaft or wheels, enabling precise control in robotics.

- Automated Systems: Rotary encoders are widely used in automation for positioning mechanisms.

- Consumer Electronics: Used in devices like volume controls, joysticks, and gaming controllers.

- Industrial Equipment: Applied in CNC machines and industrial automation for precise positioning.

Benefits of Rotary Encoder Modules

Rotary encoders provide several advantages, making them invaluable in many projects:

- High Precision: Encoders offer accurate position sensing with minimal error.

- Durability: Non-contact measurement ensures longevity and reliability.

- Compact Size: They are typically small and easy to integrate into various devices.

- Versatility: Can be used for speed, direction, and position sensing in numerous applications.

How to Choose the Right Rotary Encoder Module

Selecting the right rotary encoder module depends on your application and requirements. Key factors to consider include:

- Resolution: The number of pulses per revolution (PPR) determines the encoder’s resolution. Higher PPR means more precise position measurements.

- Accuracy: Ensure the encoder meets the accuracy requirements of your application.

- Size and Mounting: Make sure the encoder fits within the design constraints of your system.

- Signal Type: Choose between analog, digital, or quadrature signals based on your needs.

Integrating Rotary Encoder Modules with Microcontrollers

Integrating rotary encoders with microcontrollers like Arduino or Raspberry Pi is relatively straightforward. Most encoders output digital signals that can be read through digital pins on your microcontroller.

Basic Wiring and Code Example

- Connect the encoder to the microcontroller:

- The encoder has three main pins: VCC, GND, and the signal pin.

- Connect VCC to the 5V pin and GND to the ground on the microcontroller.

- Connect the signal pin to a digital input pin on the microcontroller.

- Write the code:

- Initialize the encoder as an input device.

- Read the signal on each pulse to determine the position and movement.

For an in-depth example, you can explore resources like the Arduino Rotary Encoder Tutorial.

Common Problems and Troubleshooting Tips

Rotary encoders are generally reliable, but there are some common issues that you may encounter:

- Signal Noise: Electrical interference can cause false readings. Use decoupling capacitors to minimize noise.

- Debouncing: Mechanical encoders can produce noisy signals. Software debouncing techniques can clean up the signal.

- Alignment Issues: If the encoder disk is not properly aligned with the sensor, it may cause inaccurate readings.

Future Trends in Rotary Encoder Technology

The future of rotary encoder technology looks promising with several advancements on the horizon:

- Wireless Rotary Encoders: The development of wireless rotary encoders will make it easier to integrate them into IoT devices and other wireless systems.

- Smaller and More Efficient Encoders: As technology improves, encoders are becoming more compact and energy-efficient, while maintaining high precision.

FAQs About Rotary Encoder Modules

- What is the difference between incremental and absolute encoders?

- Incremental encoders measure position changes, while absolute encoders measure the exact position.

- Can a rotary encoder be used to measure speed?

- Yes, by counting the pulses per unit of time, you can determine the speed of rotation.

- How do I connect a rotary encoder to an Arduino?

- You can connect a rotary encoder to an Arduino using digital pins for the signal and power pins for VCC and GND.

- What is the typical resolution of a rotary encoder?

- It depends on the model, but most encoders offer resolutions from 10 to 1000 pulses per revolution (PPR).

Conclusion

In conclusion, rotary encoder modules are essential components in various applications that require accurate and reliable rotational position sensing. Whether used in robotics, industrial machinery, or consumer electronics, they offer unparalleled precision in detecting rotational movement. By familiarizing yourself with the different types of rotary encoders—incremental and absolute—and their unique features, you can select the ideal module for your project needs.

Understanding how to integrate rotary encoders with microcontrollers like Arduino or Raspberry Pi is crucial for achieving smooth and responsive control in your systems. Proper wiring, calibration, and troubleshooting methods will help you avoid common pitfalls and ensure the reliability of your encoder modules in long-term use.

As technology advances, rotary encoders continue to evolve, offering even more capabilities and integration options. Exploring tutorials and real-world applications will inspire creative uses of rotary encoders in a variety of industries, from automation to IoT. By leveraging these modules effectively, you can significantly improve the functionality and precision of your projects.

Arduino Projects:

1- Complete Guide for DHT11/DHT22 Humidity and Temperature Sensor With Arduino

2- DHT11 – Temperature and Humidity Sensor

3- DHT22 – Temperature and Humidity Sensor (more accurate than DHT11)

4- BMP180 – Barometric Pressure and Altitude Sensor

5- BMP280 – Barometric Pressure & Temperature Sensor

6- BME280 – Temperature, Humidity, and Pressure Sensor

7- Arduino Flex Sensor Controlled Robot Hand

8- Arduino ECG Heart Rate Monitor AD8232 Demo

9- Arduino NRF24L01 Wireless Joystick Robot Car

10- Arduino Force Sensor Anti-Theft Alarm System

11- Arduino NRF24L01 Transceiver Controlled Relay Light

12- Arduino Rotary Encoder Controlled LEDs: A Complete Guide